HYDRO RUNNERS

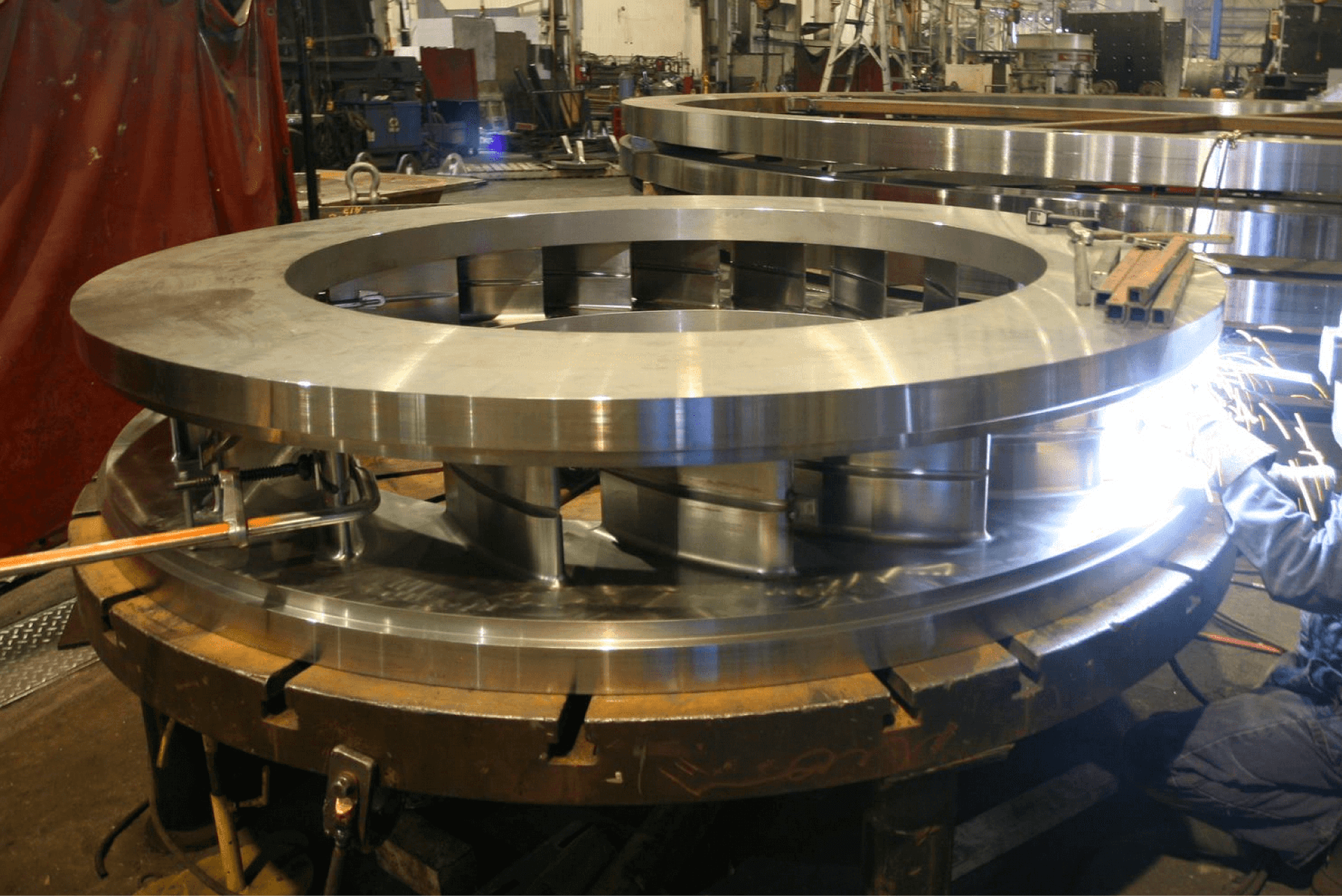

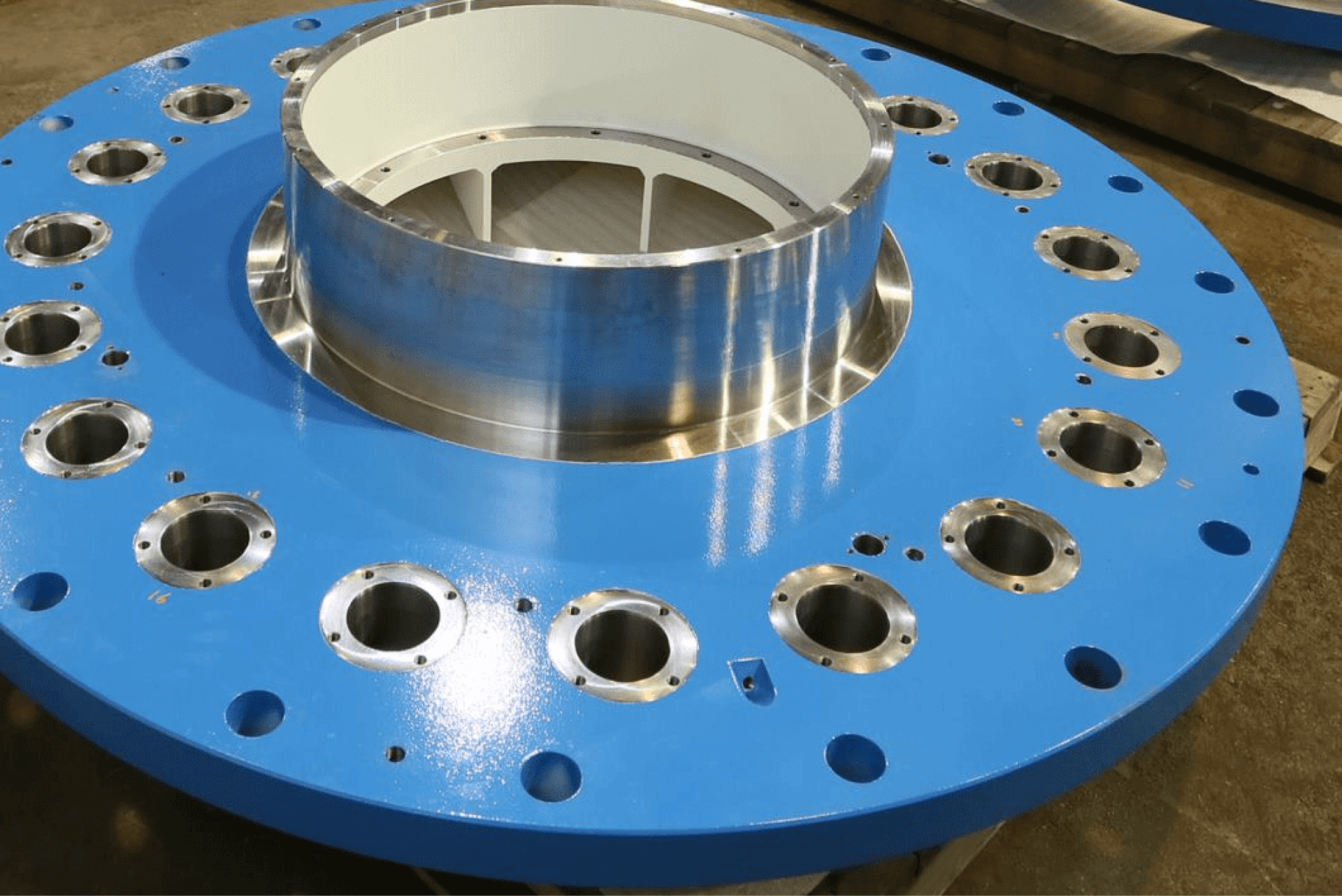

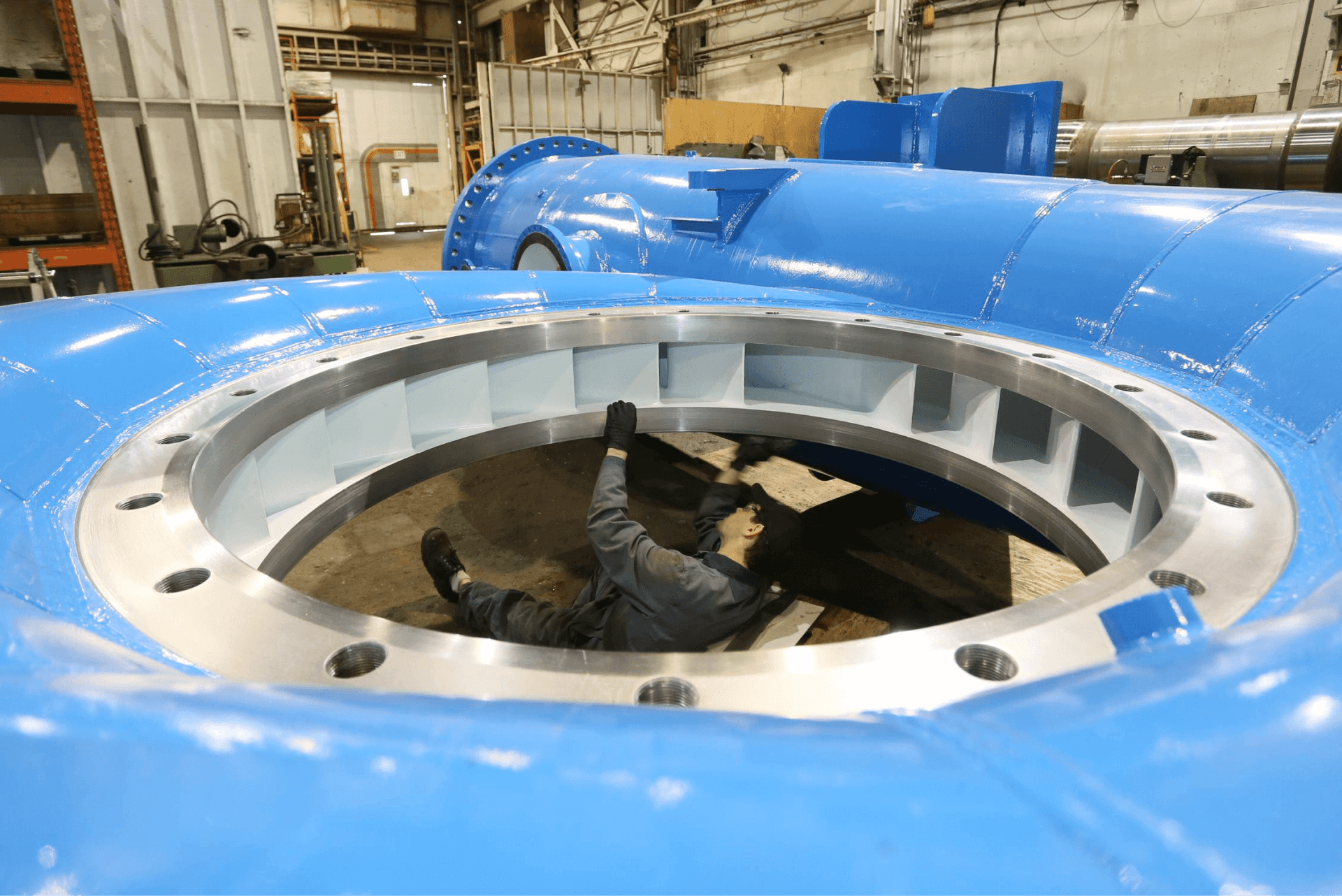

EBCO Hydro Services uses advanced German 5-axis CNC machines that are capable of maintaining absolute accuracy all the way through the manufacturing process.

Configured especially for hydro components, these digitally controlled machines are able to exactly replicate every runner surface defined in the original computer model.

EBCO’s fully automated DMG DMU 210P takes the job from a raw billet of steel all the way through machining to grinding and final polishing, achieving model accuracy ovee 4 microns, a level of accuracy unachievable by hand polishing. It’s a difference you can see in the turbine and your bottom line.

The hydraulic surfaces of EBCO turbines are uniformly smooth, and every bucket or blade is identical.

The result is a turbine with less turbulence, greater efficiency and longer life.

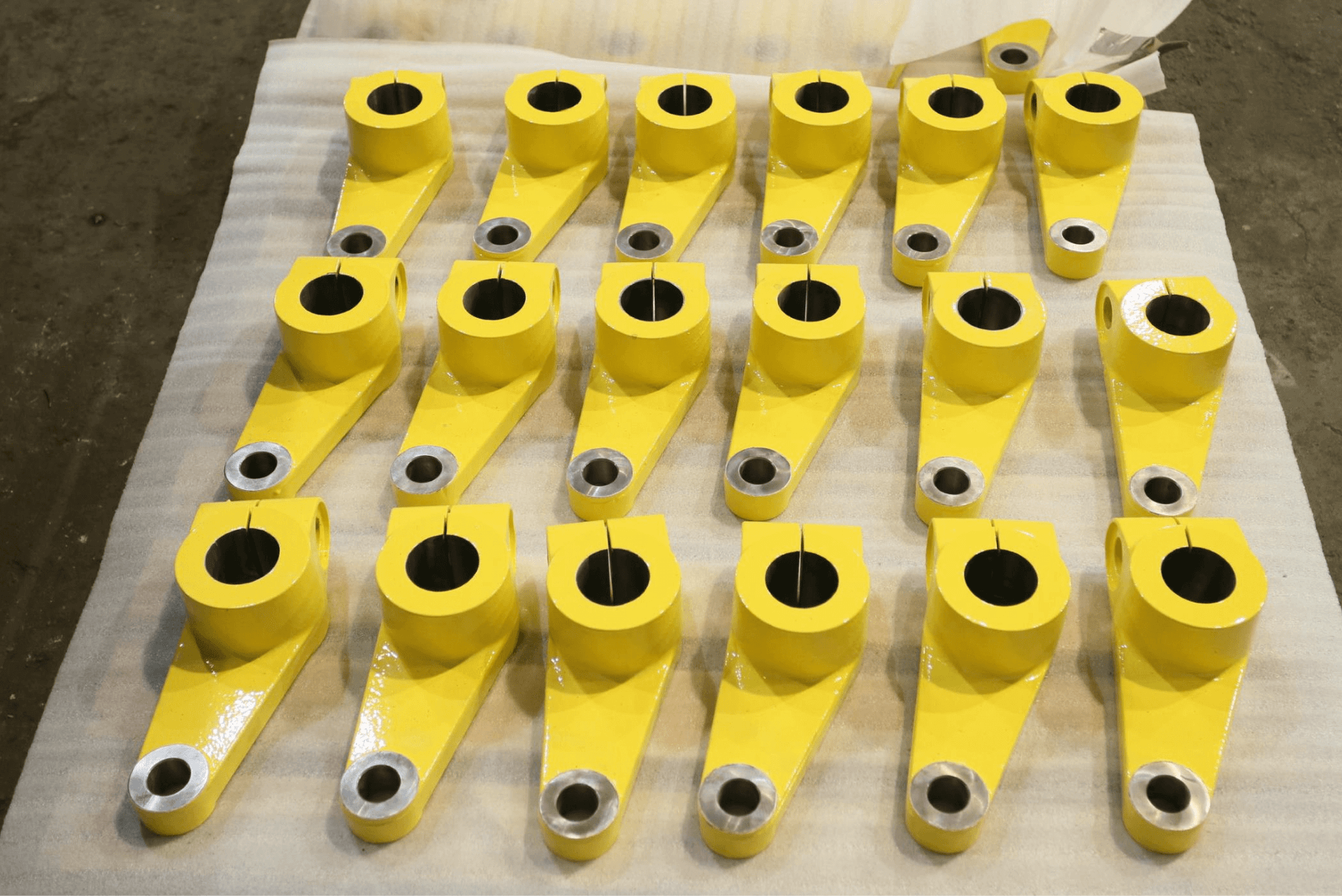

Turgo Turbine:

The Turgo turbine is an impulse water turbine designed for medium head applications. Operational Turgo turbines achieve efficiencies of about 87% and work with net heads between 15 and 300 m.[1]

Designed in 1919 by Gilkes as a modification of the Pelton wheel, the Turgo has some advantages over Francis and Pelton designs for certain applications.

First, the runner is less expensive to make than a Pelton wheel. Second, it doesn’t need an airtight housing like the Francis. Third, it has higher specific speed and can handle a greater flow than the same diameter Pelton wheel, leading to reduced generator and installation cost.

Turgos operate in a head range where the Francis and Pelton overlap. While many large Turgo installations exist, they are also popular for small hydro where low cost is very important.

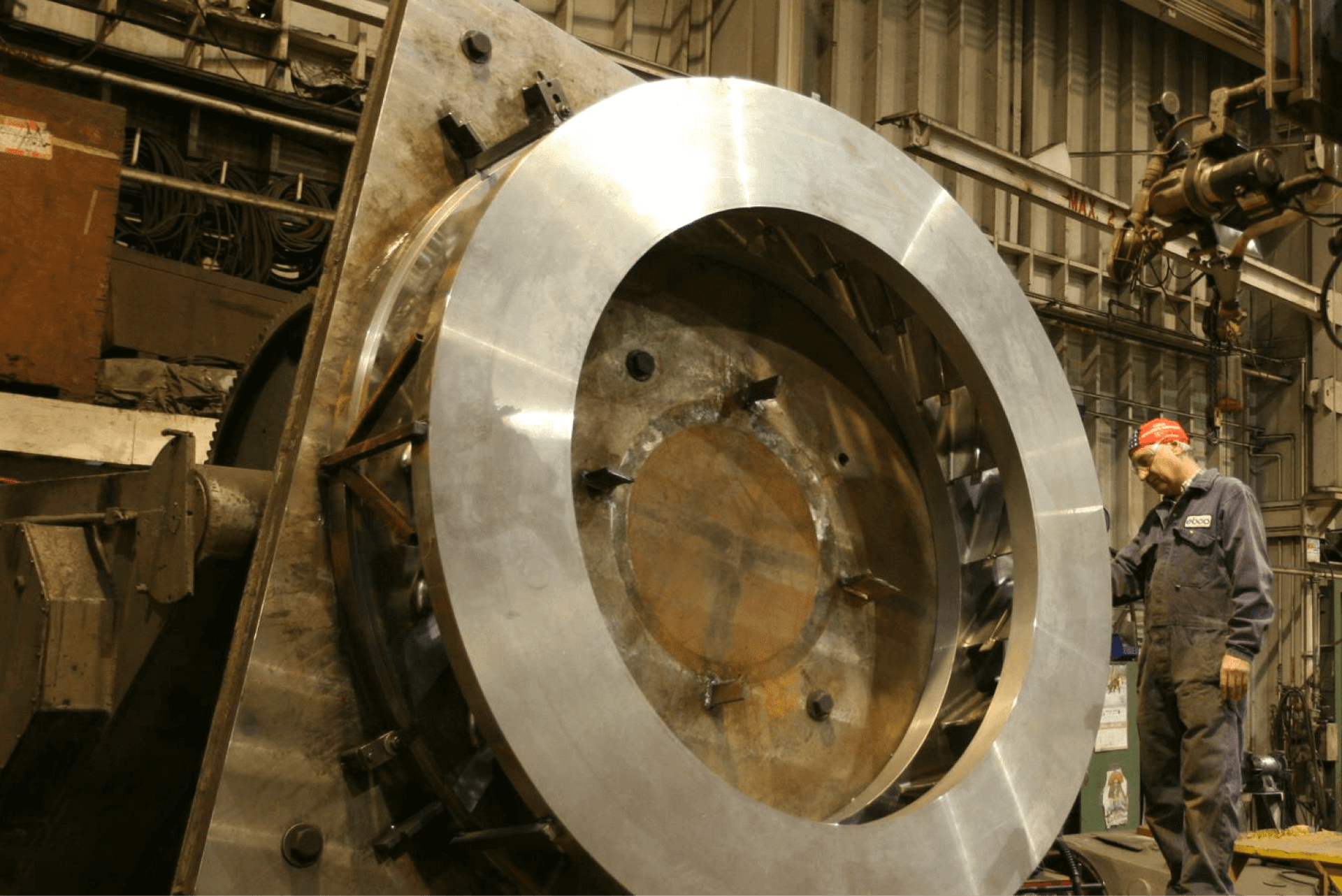

Pelton Turbines:

The ideal turbine for high heads and smaller flows.

Pelton turbines are mainly designed for applications with large heads and small water volumes. Even with fluctuating water supply these turbines achieve an optimal efficiency, since the number of used nozzles can be individually adapted.

By load changes the Pelton turbine buckets are exposed to high forces. In order to achieve high resistance of the buckets, we rely on specially milled Pelton buckets and advanced manufacturing. Whether horizontal or vertical design, one jet or up to six jets, internal or external regulation: Voith Hydro engineers, designs and produces Pelton runners tailored to the field of application to meet the need of your unit.

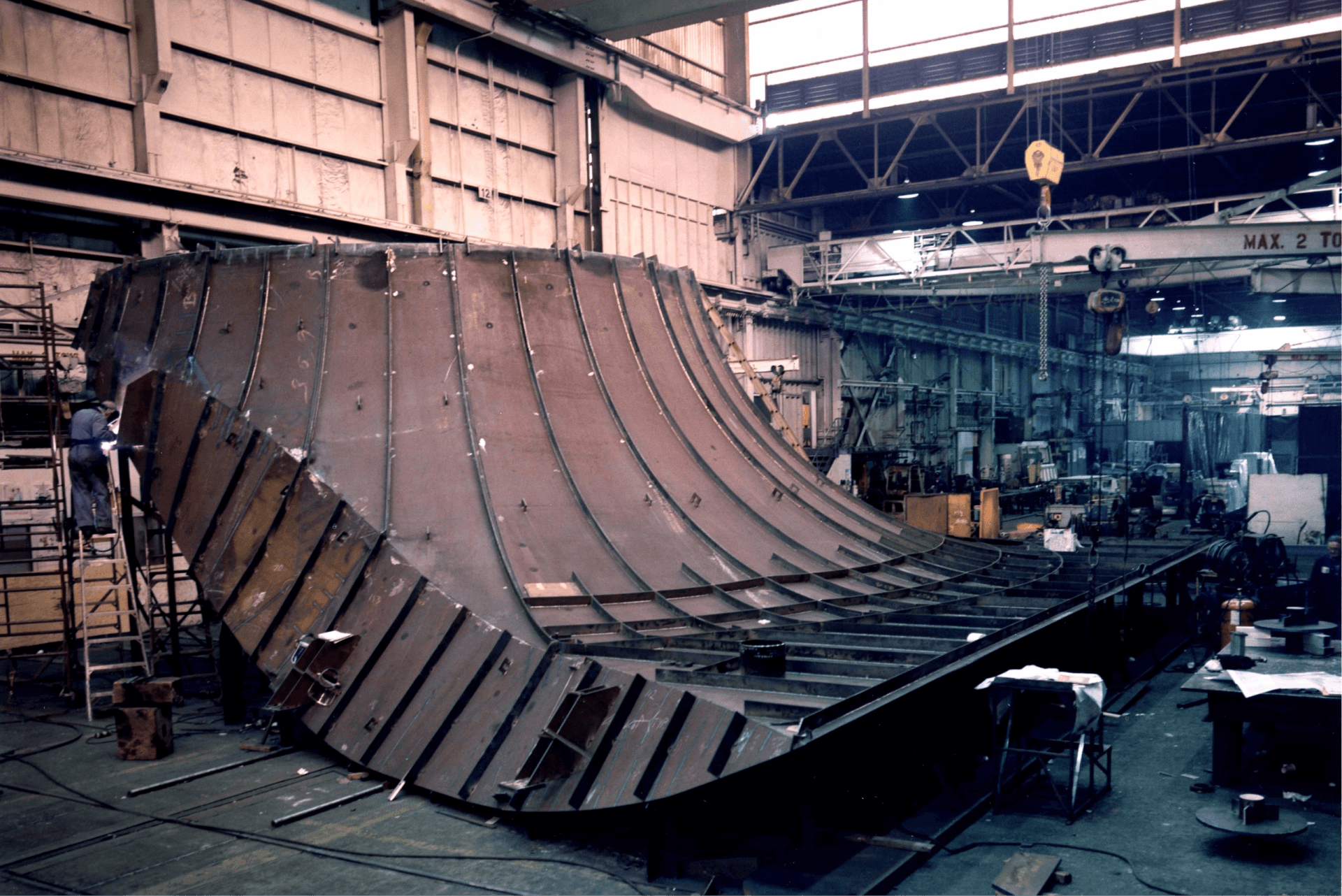

Francis Turbines:

The classic turbine for medium heads and large flow applications.

Francis turbines are primarily used in run-of-river plants and storage power stations with large flow volume. They are characterized by their optimal degree of efficiency and high speed ranges. Their special hydraulic characteristics result in comparatively high-speed compact units, right up to the largest capacities.

Voith Hydro develops and produces Francis turbines as spiral turbines, which can be used in horizontal as well as vertical design. The runner is often directly coupled to the generator shaft which ensures ideal compactness and little maintenance requirements.

Kaplan Turbines:

The optimal turbine for low head and large flows.

Based on the Francis turbine, Victor Kaplan designed the Kaplan turbine between 1910 and 1913, with Voith using it for the first time in 1922. Today, it is mainly used in small head applications and large volumes of water, such as in run-of-river plants.

Due to the flexible adjustability of the distributor and the hard coated blades Kaplan turbines enable an ideal management of heavily fluctuating water supplies. This control ensures efficiency and high output ranges.

Voith supplies vertical Kaplan turbines as well as horizontal bulb turbines in various types with three to seven blades. The drive to the generator is effected preferably via direct connection. In certain cases, flat belts or gearboxes propel the drive.